Overview

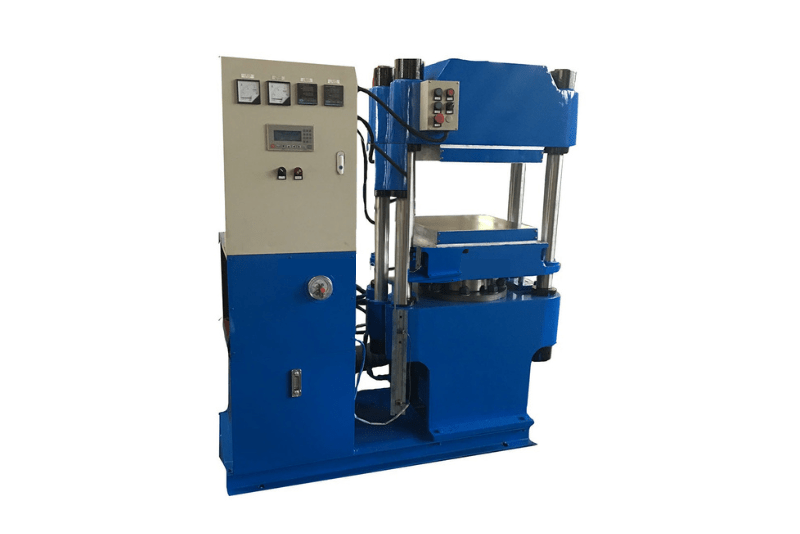

Hydraulic Presses for Molding. 4-nos Hard Chrome Pillars Type Presses are designed to provide maximum flexibility for different blanking, broaching and other applications. The change in the speed can be preset to take place at any point of the stroke with the help of limit switches / proximity switches / liner encoders / potentiometer. Maximum frame rigidity is achieved through computer aided frame design and finite element analysis. These presses can be custom designed to suit specific requirements of the customers.

Features

- These Presses provide fast approach (upto 300 mm / sec) slow pressing & fast return speed.

- Press frames are rugged, steel unit of greater strength & rigidity.

- The change in speed can be manually preset to take place at any point of the stroke with the help of limit switches / proximity switches & potentiometer or transducers.

- The frames are stress- relieved by ultrasonic vibrators.

- Maximum frame rigidity is achieved through computer aided frame design & finite element analysis.

- Extra long, precision machined & hardened guides to face slides offer exceptional accuracy & alignment which further reduced to wear.

- The low noise hydraulic power pack unit is designed as per International practices & assembled with internationally reputed make components.

- The presses are designed as per ISI guidelines, hence standard seals, bushes are used with lubrication arrangement.

- PLC can be provided in the press as per customers requirement i.e. Allan Bradley, Mitsubishi, Omron make. These offer maximum production flexibility & full compatibility with international standards.

- Precise machining of the structural members is done after normalizing to get the required accuracy like parallelism between platen & bed & right angularity between bed the moving platen.

- Lubrication – Ram slides / guides / guide bushes are lubricated from a centralized lubrication arrangement.